- Áit

- Thart ar

- Táirgeacht

- Láidreacht

- Scéal

- Lionsa

- Gabh gabhálais

- Flanges cruach dhosmálta

- Feistis feadán cruach dhosmálta

Is éard atá i gceist le flanges muineál fada weld ná síneadh ar na flanga muineál táthúcháin le necks. Is iondúil go n -úsáidtear é in iarratais a mbíonn brú ardbhrú orthu chomh maith le coinníollacha ard nó teochtaí íseal. Mar shampla i bpíblínte ola agus gáis, gléasraí próiseála ceimiceacha, agus áiseanna giniúna cumhachta.

Is flange aon phíosa brionnaithe é muineál an flange le muineál fada, barrchaolaithe agus aghaidh árasán nó aghaidh ardaithe. Ceadaíonn an muineál fada trasdul réidh ón bpíopa go dtí an flange, rud a chabhraíonn le strus a dháileadh níos cothroime agus a laghdaíonn an baol go dtarlódh tuirse. Ina theannta sin, soláthraíonn an muineál fada spás leordhóthanach le haghaidh táthú, rud a fhéadann sláine agus feidhmíocht na píblíne a fheabhsú tuilleadh.

Tá muineál na flange muineál táthú fada i bhfad níos faide ná flanges eile, agus mar sin is minic a úsáidtear é mar shuaimhneas le haghaidh bairille nó colún. Is féidir é a cheangal go díreach leis an soitheach. Ligeann sé seo dóibh a bheith ina bhfuinneog a threisítear. Ciallaíonn úsáid an chineáil flange seo gur féidir píopa chun seam weld flange a sheachaint. Soláthraíonn sé freisin na buntáistí a bhaineann le féin -fhulaingt. $ $

Tabhairt isteach

| Caighdeánach | Cruach Carbóin: ASTM A105, ASTM A350 LF1 / LF2, S235JR, P245GH, P250GH, P280GH, A694 F42 / 46/52/56/0/65/70, srl Cruach dhosmálta: ASTM A182 F304/304L/304H, F316/316L, F317/317L, F321, F310, F347, srl. Cruach cóimhiotail: ASTM A 182 F1/ F5/ F9/ F11/ F22/ F91/ ETC. Cruach Duplex agus Super Duplex: ASTM A815 UNS S31803/S32205/S32750/S32760 |

| Ábhar | A182 F304/304L, F316/316L, 317, 321, 310S, 316TI, 316H.317H.317L. 904L, 321H, 347H, 310H, UNS31803, UNS32750, UNS32760, Nickel Alloy Inconel 600, Inconel 625, Inconel 601, Inconel 690, Incoloy 600h, Inconel 718, Incoloy 800, Incoloy 825, Incoloy 800h, C-200, CALOY 400, MOLOY 800, Incoloy 800h 800h, COLOY 800, COLOY 800, MONOY 800, MONOY 800, MOLOY 800, MONOY 800, srl. |

| Tar chun tosaigh | Cosc meirge, sciath phéinte dubh nó cóireáil fosfáite le dath dubh, sciath péint vearnais, sciath ola vearnais, sciath leictreamaigh galbhánuithe |

| Tíopáil | Brionnaithe, cóireáilte teasa agus machined |

| méid | 1/2 "-48" |

| Am seachadta | Laistigh de 5-30 lá tar éis an réamhíoctha a fháil |

| Pacáil | Mála plaisteach inmheánach, cartán seachtrach, agus cás sraithadhmaid nó pailléid nó de réir riachtanas an chliaint |

| Iarrchán | Oibreacha Uisce, Tionscal Longthógála, Tionscal Peitriceimiceach & Gáis, Cumhacht |

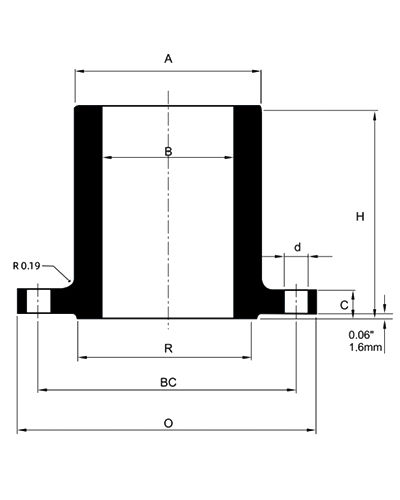

Lamháltais flange

Nóta Ginearálta: Tá toisí i orlach.

|

| |

| Trastomhas lasmuigh (Toise O) | OD <12 ± 0.060 OD> 12, <24 ± 0.120 OD> 24 ± 0.190 |

|

|

|

| Tiús flange min (toise c) | Gach méiD NPS 18 agus 0.120 níos lú, -zero NPS 20 agus níos mó 0.190, -zero |

| Bevel trastomhas an mhoil (toise A) | Gach méiD 0.120, -zero |

| FaD trí mhol (Toise H) | NPS 4 agus níos lú ± 0.060 NPS 5 go 10, Cuimsitheach 0.060, -0.120 NPS 12 agus níos mó 0.120, -0.180 |

| Trastomhas tollaDh (toise B) | NPS 10 agus níos lú ± 0.030 NPS 12 go 18, cuimsitheach ± 0.060 NPS 20 agus níos mó 0.120, -0.060 |

| AghaiDheanna | *AirDe os comhair ± 0.010 Trastomhas aghaiDh ardaithe (toise R) Aicme 150, 300 (0.06 in aghaidh ardaithe) ± 0.030 Aicme 400 (0.25 in aghaidh ardaithe) ± 0.020 Comhpháirtí Cineál Fáinne 0.020, -zero Trastomhais taobh istigh agus taobh amuigh de bheag agus beag Teanga, groove, fireann, agus baineann R, S, T, U, W, X, Y & Z ± 0.020 K&L 0.020, -zero Fáinne comhpháirteach os comhair Doimhneacht (Toise E) 0.016, -zero Leithead (toise f) ± 0.008 Trastomhas na páirce (Toise P) ± 0.005 Ga ag an mbun (toise r) R <0.060 0.030, -zero R> 0.060 ± 0.030 Uillinn 23 céim ± ½ deg. |

| Druileáil agus os comhair | Trastomhas an chiorcail bolt ± 0.060 Lár go lár na bpoll bolt in aice láimhe ± 0.030 Éicea -chomhréireacht idir ciorcal bolt agus trastomhas agus trastomhais os comhair machined NPS 2 ½ $ $ agus níos lú ± 0.030 NPS 3 agus níos mó ± 0.060 *Trastomhas poill bolt ± 0.020 |

Aicme150

| Ainmniúil Méid píopaí (I) | Lasmuigh Lárlíne (Mm) | Tiús de flange Min. (Mm) | O.D. De Ardaithe Dánacht (Mm) | Mol Lárlíne ag Bevel (Mm) | Lárlíne de tolladh (Mm) | Ar fad I measc Mol (Mm) | Druileála | ||

| Lárlíne de bolt Bair ag (Mm) | Uimhir a chur ar de phoill | Lárlíne de phoill (Mm) | |||||||

| - | O | C | R | A | B | H | BC | - | d |

| ½ | 89.0 | 11.1 | 34.9 | 30.2 | 12.7 | 228.6 | 60.5 | 4 | 15.8 |

| ¾ | 95.8 | 12.7 | 42.9 | 38.1 | 19.1 | 228.6 | 69.9 | 4 | 15.8 |

| 1 | 10.8.0 | 14.3 | 50.8 | 50.8 | 25.4 | 228.6 | 79.4 | 4 | 15.8 |

| 1 ¼ | 117.5 | 15.9 | 63.5 | 60.3 | 31.8 | 228.6 | 88.9 | 4 | 15.8 |

| 1 ½ | 127.0 | 17.5 | 73.0 | 66.7 | 38.1 | 228.6 | 98.4 | 4 | 15.8 |

| 2 | 152.5 | 19.1 | 92.1 | 82.5 | 50.8 | 228.6 | 120.7 | 4 | 19.0 |

| 2 ½ | 178.0 | 22.2 | 104.8 | 95.2 | 63.5 | 228.6 | 139.7 | 4 | 19.0 |

| 3 | 190.5 | 23.8 | 127.0 | 107.9 | 76.2 | 228.6 | 152.4 | 4 | 19.0 |

| 3 ½ | 216.0 | 23.8 | 139.9 | 124.0 | 88.9 | 228.6 | 177.8 | 8 | 19.0 |

| 4 | 228.5 | 23.8 | 157.2 | 139.7 | 101.6 | 228.6 | 190.5 | 8 | 19.0 |

| 5 | 254.0 | 23.8 | 185.7 | 165.1 | 127.0 | 228.6 | 215.9 | 8 | 22.5 |

| 6 | 279.5 | 25.4 | 215.9 | 196.8 | 152.4 | 228.6 | 241.3 | 8 | 22.5 |

| 8 | 343.0 | 28.6 | 269.9 | 247.6 | 203.2 | 228.6 | 298.4 | 8 | 22.5 |

| 10 | 406.5 | 30.2 | 323.9 | 304.8 | 254.0 | 228.6 | 361.9 | 12 | 25.5 |

| 12 | 482.5 | 31.8 | 381.0 | 365.1 | 304.8 | 228.6 | 431.8 | 12 | 25.5 |

| 14 | 533.5 | 34.9 | 412.8 | 406.4 | 355.6 | 228.6 | 476.2 | 12 | 28.5 |

| 16 | 597.0 | 36.5 | 469.9 | 457.2 | 406.4 | 228.6 | 539.7 | 16 | 28.5 |

| 18 | 635.0 | 39.7 | 533.4 | 508.0 | 457.2 | 228.6 | 577.8 | 16 | 31.8 |

| 20 | 698.5 | 42.9 | 584.2 | 558.8 | 508.0 | 228.6 | 635.0 | 20 | 31.8 |

| 24 | 813.0 | 47.0 | 692.2 | 666.7 | 609.6 | 228.6 | 749.3 | 20 | 35.1 |

Aicme300

| Ainmniúil Méid píopaí (I) | Lasmuigh Lárlíne (Mm) | Tiús de flange Min. (Mm) | O.D. De Ardaithe Dánacht (Mm) | Mol Lárlíne ag Bevel (Mm) | Lárlíne de tolladh (Mm) | Ar fad I measc Mol (Mm) | Druileála | ||

| Lárlíne de bolt Bair ag (Mm) | Uimhir a chur ar de phoill (PC) | Lárlíne de phoill (Mm) | |||||||

| - | O | C | R | A | B | H | BC | - | d |

| ½ | 95.5 | 14.3 | 34.9 | 38.1 | 12.7 | 228.6 | 66.7 | 4 | 15.8 |

| ¾ | 117.5 | 15.9 | 42.9 | 47.6 | 19.1 | 228.6 | 82.5 | 4 | 19.0 |

| 1 | 124.0 | 17.5 | 50.8 | 54.0 | 25.4 | 228.6 | 88.9 | 4 | 19.0 |

| 1 ¼ | 133.5 | 19.1 | 63.5 | 63.5 | 31.8 | 228.6 | 98.4 | 4 | 19.0 |

| 1 ½ | 155.5 | 20.6 | 73.0 | 69.8 | 38.1 | 228.6 | 114.3 | 4 | 22.5 |

| 2 | 165.0 | 22.2 | 92.1 | 82.5 | 50.8 | 228.6 | 127.0 | 8 | 19.0 |

| 2 ½ | 190.5 | 25.4 | 104.8 | 100.0 | 63.5 | 228.6 | 149.2 | 8 | 22.5 |

| 3 | 209.5 | 28.6 | 127.0 | 117.5 | 76.2 | 228.6 | 168.3 | 8 | 22.5 |

| 3 ½ | 228.5 | 30.2 | 139.7 | 133.4 | 88.9 | 228.6 | 184.1 | 8 | 22.5 |

| 4 | 254.0 | 31.8 | 157.2 | 146.0 | 101.6 | 228.6 | 200.0 | 8 | 22.5 |

| 5 | 279.5 | 34.9 | 185.7 | 177.8 | 127.0 | 228.6 | 234.9 | 8 | 22.5 |

| 6 | 317.5 | 36.5 | 215.9 | 206.4 | 152.4 | 228.6 | 269.9 | 12 | 22.5 |

| 8 | 381.0 | 41.3 | 269.9 | 260.3 | 203.2 | 228.6 | 330.2 | 12 | 25.5 |

| 10 | 444.5 | 47.6 | 323.9 | 320.7 | 254.0 | 228.6 | 387.3 | 16 | 28.5 |

| 12 | 520.5 | 50.8 | 381.0 | 374.6 | 304.8 | 228.6 | 450.8 | 16 | 31.8 |

| 14 | 584.0 | 54.0 | 412.8 | 425.4 | 355.6 | 228.6 | 514.3 | 20 | 31.8 |

| 16 | 64.7 | 57.2 | 469.9 | 482.6 | 406.4 | 228.6 | 571.5 | 20 | 35.1 |

| 18 | 711.0 | 60.3 | 533.4 | 533.4 | 457.2 | 228.6 | 628.6 | 24 | 35.1 |

| 20 | 774.5 | 63.5 | 584.2 | 587.3 | 508.0 | 228.6 | 685.8 | 24 | 35.1 |

| 24 | 914.5 | 69.9 | 692.2 | 701.6 | 609.6 | 228.6 | 812.8 | 24 | 41.2 |

Aicme400

| Ainmniúil Méid píopaí (I) | Lasmuigh Lárlíne (Mm) | Tiús de flange Min. (Mm) | O.D. De Ardaithe Dánacht (Mm) | Mol Lárlíne ag Bevel (Mm) | Lárlíne de tolladh (Mm) | Ar fad I measc Mol (Mm) | Druileála | ||

| Lárlíne de bolt Bair ag (Mm) | Uimhir a chur ar de phoill (PC) | Lárlíne de phoill (Mm) | |||||||

| - | O | C | R | A | B | H | BC | - | d |

| 1 | 124.0 | 17.5 | 50.8 | 54.0 | 25.4 | 228.6 | 88.9 | 4 | 19.0 |

| 1 ¼ | 133.5 | 20.6 | 63.5 | 63.5 | 31.8 | 228.6 | 98.4 | 4 | 19.0 |

| 1 ½ | 155.5 | 22.2 | 73.0 | 69.8 | 38.1 | 228.6 | 114.3 | 4 | 22.5 |

| 2 | 165.0 | 25.4 | 92.1 | 82.5 | 50.8 | 228.6 | 127.0 | 8 | 19.0 |

| 2 ½ | 190.5 | 28.6 | 104.8 | 100.0 | 63.5 | 228.6 | 149.2 | 8 | 22.5 |

| 3 | 209.5 | 31.8 | 127.0 | 117.5 | 76.2 | 228.6 | 168.1 | 8 | 22.5 |

| 3 ½ | 228.5 | 34.9 | 139.7 | 133.4 | 88.9 | 228.6 | 184.2 | 8 | 25.5 |

| 4 | 254.0 | 34.9 | 157.2 | 146.0 | 101.6 | 228.6 | 200.0 | 8 | 25.5 |

| 5 | 279.5 | 38.1 | 185.7 | 177.8 | 127.0 | 228.6 | 234.9 | 8 | 25..5 |

| 6 | 317.5 | 41.3 | 215.9 | 206.4 | 152.4 | 228.6 | 269.9 | 12 | 25.5 |

| 8 | 381.0 | 47.6 | 269.9 | 260.3 | 203.2 | 228.6 | 330.2 | 12 | 28.5 |

| 10 | 444.5 | 54.0 | 323.9 | 320.7 | 254.0 | 228.6 | 387.3 | 16 | 31.8 |

| 12 | 520.5 | 57.2 | 381.0 | 374.6 | 304.8 | 228.6 | 450.8 | 16 | 35.1 |

| 14 | 584.0 | 60.3 | 412.8 | 425.4 | 355.6 | 228.6 | 514.3 | 20 | 35.1 |

| 16 | 647.5 | 63.5 | 469.9 | 482.6 | 406.4 | 228.6 | 571.5 | 20 | 38.1 |

| 18 | 711.0 | 66.7 | 533.4 | 533.4 | 457.2 | 228.6 | 628.6 | 24 | 38.1 |

| 20 | 774.5 | 69.9 | 584.2 | 587.3 | 508.0 | 228.6 | 685.8 | 24 | 41.2 |

| 24 | 914.5 | 76.2 | 692.2 | 701.6 | 609.6 | 228.6 | 812.8 | 24 | 47.8 |

Aicme600

| Ainmniúil Méid píopaí (I) | Lasmuigh Lárlíne (Mm) | Tiús de flange Min. (Mm) | O.D. De Ardaithe Dánacht (Mm) | Mol Lárlíne ag Bevel (Mm) | Lárlíne de tolladh (Mm) | Ar fad I measc Mol (Mm) | Druileála | ||

| Lárlíne de bolt Bair ag (Mm) | Uimhir a chur ar de phoill (PC) | Lárlíne de phoill (Mm) | |||||||

| - | O | C | R | A | B | H | BC | - | d |

| 1 | 124.0 | 17.5 | 50.8 | 54.0 | 25.4 | 228.6 | 88.9 | 4 | 19.0 |

| 1 ¼ | 133.5 | 20.6 | 63.5 | 63.5 | 31.8 | 228.6 | 98.4 | 4 | 19.0 |

| 1 ½ | 155.5 | 22.2 | 73.0 | 69.8 | 38.1 | 228.6 | 114.3 | 4 | 22.5 |

| 2 | 165.0 | 25.4 | 92.1 | 82.5 | 50.8 | 228.6 | 127.0 | 8 | 19.0 |

| 2 ½ | 190.5 | 28.6 | 104.8 | 100.0 | 63.5 | 228.6 | 149.2 | 8 | 22.5 |

| 3 | 209.5 | 31.8 | 127.0 | 117.5 | 76.2 | 228.6 | 168.1 | 8 | 22.5 |

| 3 ½ | 228.5 | 34.9 | 139.7 | 133.4 | 88.9 | 228.6 | 184.2 | 8 | 25.5 |

| 4 | 273.0 | 38.1 | 157.2 | 152.4 | 101.6 | 228.6 | 215.9 | 8 | 25.5 |

| 5 | 330.0 | 44.5 | 185.7 | 190.5 | 127.0 | 228.6 | 266.7 | 8 | 28.5 |

| 6 | 355.5 | 47.6 | 215.9 | 222.2 | 152.4 | 228.6 | 292.1 | 12 | 28.5 |

| 8 | 419 | 55.6 | 269.9 | 273.0 | 203.2 | 228.6 | 349.3 | 12 | 31.8 |

| 10 | 508.0 | 63.5 | 323.9 | 342.9 | 254.0 | 228.6 | 431.8 | 16 | 35.1 |

| 12 | 559.0 | 66.7 | 381.0 | 400.0 | 304.8 | 228.6 | 489.0 | 20 | 35.1 |

| 14 | 603.5 | 69.9 | 412.8 | 431.8 | 355.6 | 228.6 | 527.1 | 20 | 38.1 |

| 16 | 686.0 | 76.2 | 469.9 | 495.3 | 406.4 | 228.6 | 603.3 | 20 | 412 |

| 18 | 743.0 | 82.6 | 533.4 | 546.1 | 457.2 | 228.6 | 654.1 | 20 | 44.5 |

| 20 | 813.0 | 88.9 | 584.2 | 609.6 | 508.0 | 228.6 | 723.9 | 24 | 44.5 |

| 24 | 940.0 | 101.6 | 692.2 | 717.5 | 609.6 | 228.6 | 838.2 | 24 | 50.8 |

Aicme900

| Ainmniúil Méid píopaí (I) | Lasmuigh Lárlíne (Mm) | Tiús de flange Min. (Mm) | O.D. De Ardaithe Dánacht (Mm) | Mol Lárlíne ag Bevel (Mm) | Lárlíne de tolladh (Mm) | Ar fad I measc Mol (Mm) | Druileála | ||

| Lárlíne de bolt Bair ag (Mm) | Uimhir a chur ar de phoill (PC) | Lárlíne de phoill (Mm) | |||||||

| - | O | C | R | A | B | H | BC | - | d |

| 1 | 149.5 | 28.6 | 50.8 | 52.4 | 25.4 | 228.6 | 101.6 | 4 | 25.5 |

| 1 ¼ | 159.0 | 28.6 | 63.5 | 63.5 | 31.8 | 228.6 | 111.1 | 4 | 25.5 |

| 1 ½ | 178.0 | 31.8 | 73.0 | 69.9 | 38.1 | 228.6 | 123.8 | 4 | 28.5 |

| 2 | 216.0 | 38.1 | 92.1 | 104.8 | 50.8 | 228.6 | 165.1 | 8 | 25.5 |

| 2 ½ | 244.5 | 41.3 | 104.8 | 123.8 | 63.5 | 228.6 | 190.5 | 8 | 28.5 |

| 3 | 241.5 | 38.1 | 127.0 | 127.0 | 76.2 | 228.6 | 190.5 | 8 | 25.5 |

| 4 | 292.0 | 44.5 | 157.2 | 158.7 | 101.6 | 228.6 | 235.0 | 8 | 31.8 |

| 5 | 349.5 | 50.8 | 185.7 | 190.5 | 127.0 | 228.6 | 279.4 | 8 | 35.1 |

| 6 | 381.0 | 55.6 | 215.9 | 235.0 | 152.4 | 228.6 | 317.5 | 12 | 31.8 |

| 8 | 470.0 | 63.5 | 269.9 | 298.5 | 203.2 | 228.6 | 393.7 | 12 | 38.1 |

| 10 | 546.0 | 69.9 | 323.9 | 368.3 | 254.0 | 228.6 | 469.9 | 16 | 38.1 |

| 12 | 609.5 | 79.4 | 381.0 | 419.1 | 304.8 | 228.6 | 533.5 | 20 | 38.1 |

| 14 | 641.5 | 85.7 | 412.8 | 450.9 | 355.6 | 228.6 | 558.8 | 20 | 41.0 |

| 16 | 705.0 | 88.9 | 469.9 | 508.0 | 406.4 | 228.6 | 616.0 | 20 | 44.5 |

| 18 | 787.5 | 101.6 | 533.4 | 565.2 | 457.2 | 228.6 | 685.8 | 20 | 50.8 |

| 20 | 857.5 | 108.0 | 584.2 | 622.3 | 508.0 | 228.6 | 749.3 | 20 | 54.0 |

| 24 | 1014.5 | 139.7 | 692.2 | 749.3 | 609.6 | 228.6 | 901.7 | 20 | 66.5 |

Aicme1500

| Ainmniúil Méid píopaí (I) | Lasmuigh Lárlíne (Mm) | Tiús de flange Min. (Mm) | O.D. De Ardaithe Dánacht (Mm) | Mol Lárlíne ag Bevel (Mm) | Lárlíne de tolladh (Mm) | Ar fad I measc Mol (Mm) | Druileála | ||

| Lárlíne de bolt Bair ag (Mm) | Uimhir a chur ar de phoill (PC) | Lárlíne de phoill (Mm) | |||||||

| - | O | C | R | A | B | H | BC | - | d |

| 1 | 149.5 | 28.6 | 50.8 | 52.4 | 25.4 | 228.6 | 101.6 | 4 | 25.5 |

| 1 ¼ | 159.0 | 28.6 | 63.5 | 63.5 | 31.8 | 228.6 | 111.1 | 4 | 25.5 |

| 1 ½ | 178.0 | 31.8 | 73.0 | 69.9 | 38.1 | 228.6 | 123.8 | 4 | 28.5 |

| 2 | 216.0 | 38.1 | 92.1 | 104.8 | 50.8 | 228.6 | 165.1 | 8 | 25.5 |

| 2 ½ | 244.5 | 41.3 | 104.8 | 123.8 | 63.5 | 228.6 | 190.5 | 8 | 28.5 |

| 3 | 267.0 | 47.6 | 127.0 | 133.4 | 762 | 228.6 | 203.2 | 8 | 31.8 |

| 4 | 311.0 | 54.0 | 157.2 | 161.9 | 101.6 | 228.6 | 241.3 | 8 | 35.1 |

| 5 | 374.5 | 73.0 | 185.7 | 196.9 | 127.0 | 228.6 | 292.1 | 8 | 41.0 |

| 6 | 393.5 | 82.6 | 215.9 | 228.6 | 152.4 | 228.6 | 317.5 | 12 | 38.1 |

| 8 | 483.0 | 92.1 | 269.9 | 292.1 | 203.2 | 228.6 | 393.7 | 12 | 44.5 |

| 10 | 584.0 | 108.0 | 323.9 | 368.3 | 254.0 | 406.4 | 482.6 | 12 | 50.8 |

| 12 | 673.0 | 123.8 | 381.0 | 450.9 | 304.8 | 406.4 | 571.5 | 16 | 54.0 |

| 14 | 749.5 | 133.4 | 412.8 | 495.3 | 355.6 | - | 635.0 | 16 | 60.5 |

| 16 | 825.5 | 146.1 | 469.9 | 552.6 | 406.4 | - | 704.9 | 16 | 66.5 |

| 18 | 914.5 | 161.9 | 533.4 | 596.9 | 457.2 | - | 774.7 | 16 | 73.0 |

| 20 | 984.0 | 177.8 | 584.2 | 641.4 | 508.0 | - | 831.9 | 16 | 79.5 |

| 24 | 1168.5 | 203.2 | 692.2 | 762.0 | 609.6 | - | 9910.6 | 16 | 920 |

Class2500

| Ainmniúil Méid píopaí (I) | Lasmuigh Lárlíne (Mm) | Tiús de flange Min. (Mm) | O.D. De Ardaithe Dánacht (Mm) | Mol Lárlíne ag Bevel (Mm) | Lárlíne de tolladh (Mm) | Ar fad I measc Mol (Mm) | Druileála | ||

| Lárlíne de bolt Bair ag (Mm) | Uimhir a chur ar de phoill (PC) | Lárlíne de phoill (Mm) | |||||||

| - | O | C | R | A | B | H | BC | - | d |

| 1 | 159.0 | 34.9 | 50.8 | 57.2 | 25.4 | 228.6 | 108.0 | 4 | 25.5 |

| 1 ¼ | 184.0 | 38.1 | 63.5 | 73.0 | 31.8 | 228.6 | 130.2 | 4 | 28.5 |

| 1 ½ | 203.0 | 44.5 | 73.0 | 79.4 | 38.1 | 228.6 | 146.1 | 4 | 31.8 |

| 2 | 235.0 | 50.8 | 92.1 | 95.3 | 50.8 | 228.6 | 171.5 | 8 | 28.5 |

| 2 ½ | 267.0 | 57.2 | 104.8 | 114.3 | 63.5 | 228.6 | 196.9 | 8 | 31.8 |

| 3 | 305.0 | 66.7 | 127.0 | 133.4 | 76.2 | 228.6 | 228.6 | 8 | 35.0 |

| 4 | 355.5 | 76.2 | 157.2 | 165.1 | 101.6 | 228.6 | 273.1 | 8 | 41.0 |

| 5 | 419.0 | 92.1 | 185.7 | 203.2 | 127.0 | 228.6 | 323.9 | 8 | 48.0 |

| 6 | 483.0 | 108.0 | 215.9 | 235.0 | 152.4 | 228.6 | 368.3 | 8 | 54.0 |

| 8 | 552.5 | 127.0 | 269.9 | 304.8 | 203.2 | 228.6 | 438.2 | 12 | 54.0 |

| 10 | 673.0 | 165.1 | 323.9 | 374.7 | 254.0 | 406.4 | 539.8 | 12 | 66.5 |

| 12 | 762.0 | 184.2 | 381.0 | 441.3 | 304.8 | 406.4 | 619.1 | 12 | 73.0 |

Bunaithe i 2007 agus bhog sé go Crios Forbartha Eacnamaíochta Longyou, Zhejiang Province, i 2022. Clúdaíonn sé achar de 130,000 méadar cearnach, níos mó ná 30 líne táirgthe, 300 oibrí, 20 duine T&F, 30 duine cigireachta agus aschur bliantúil de 50,000 tonna.

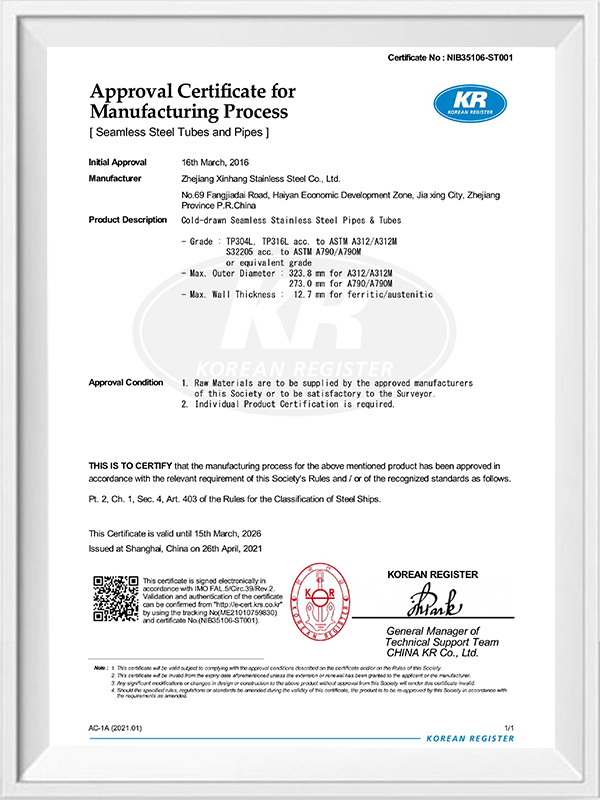

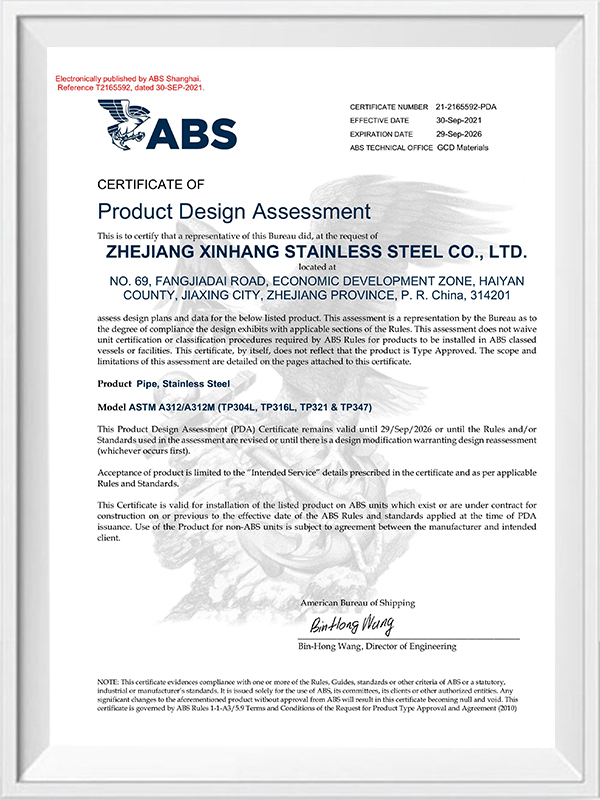

Tá Córas Bainistíochta Cáilíochta ISO9001: 2008 rite aige, PED 97/23/CE deimhniú Trealamh Brú Trealamh Brú, Ceadúnas Déantúsaíochta Trealamh Speisialta na Síne (Feadán Brú) TS, Deimhniú ASME, Córas Bainistíochta Caighdeánaithe Fiontraíochta Cúige, Córas Bainistíochta Comhshaoil 2004, Clár Glan (Fiontraíocht Ghlas), agus sraith de theastas, Clár na Breataine), Clár na Breataine) de Chlár na Breataine), agus Sraith de Chlár na Breataine de Chumann Classification) na Breataine), agus: de loingseoireacht (LR), Deutsche Veritas (GL), Bureau Veritas Society (BV), Deimhniú Monarcha Norske Veritas (DNV), agus Deimhniú Monarcha Chlár Loingseoireachta na Cóiré (KR).

I measc na bpríomhtháirgí tá píopaí cruach dhosmálta, feistis phíobáin, flanges, comhlaí, etc., a úsáidtear go forleathan i peitriliam, tionscal ceimiceach, tionscal núicléach, bruithniú, longthógáil, cógaisíocht, bia, caomhnóireacht uisce, cumhacht leictreach, fuinneamh nua, trealamh meicniúil, agus páirceanna eile. Cloíonn an chuideachta leis an tenet corparáideach de "cháilíocht le haghaidh marthanais, cáil ar fhorbairt" agus freastalaíonn sé go dílis ar gach custaiméir chun cás buaiteach a chruthú.

An rogha uirlis bladhmála is fearr le haghaidh feadáin cruach dhosmálta Bain úsáid as uirlis bhladhmála ardghiarála 37° (AN/JIC) nó 45° (SAE) atá rátáilte le haghaidh cruach dhosmálta,...

Féach níos móBun líne: conas píopa cruach dhosmálta a tháthú gan siúcra agus sceitheadh Don chuid is mó de phíobáin déanta as cruach dhosmálta, is é an cosán is iontaofa chun welds glan, creimthe-resis...

Féach níos móFreagra díreach: cad a chiallaíonn “rátáil brú píopa cruach dhosmálta” i ndáiríre Níl rátáil brú uilíoch amháin ag píopa cruach dhosmálta. Is é an “rátáil brú píopa cruach dhosmálta”...

Féach níos móNí roinnfimid do sheoladh ríomhphoist go deo agus tusa

Is féidir linn diúltú ag am ar bith, geallaimid.